How to Become a CNC Machinist: Career Paths, Training & Growth Opportunities

Computer numerical control (CNC) machining is widely recognized as a rewarding, high-demand skilled trade, offering strong job security, competitive pay, and significant opportunities for advancement. Multiple pathways into the profession exist, making it accessible and adaptable for different types of learners. Educational Paths to Becoming a CNC Machinist While becoming a CNC machinist doesn’t always […]

Ontario’s Pivotal Role in the Global Aerospace Supply Chain

Ontario has a strong reputation as one of the aerospace industry leaders in Canada and globally. The sector contributes around $6.5 billion annually to the economy, accounting for 30% of Canada’s aerospace sector. Ontario’s aerospace industry plays a critical role in global supply chains. Although one can find components manufactured in the province in virtually […]

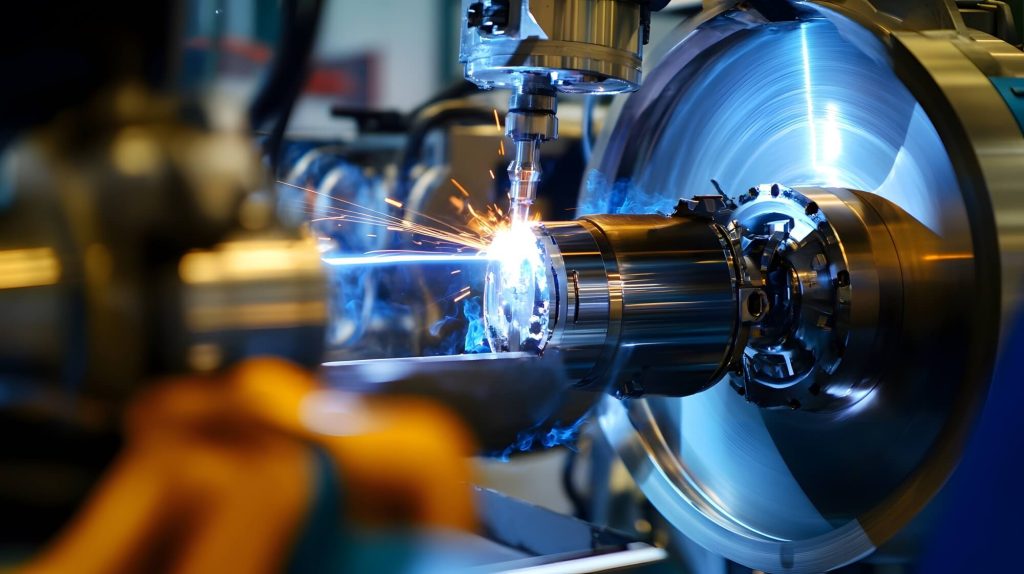

How CNC Prototyping Fuels Defence Innovation and Agility

CNC prototyping plays a vital role in the defence sector by enabling precise and rapid development of complex parts. CNC machining offers an opportunity to produce complex prototype components to the highest standards of accuracy and quality, ultimately leading to advanced defence solutions capable of meeting stringent military requirements. CNC Machining’s Role in Defence Innovation […]

Precision Automation in High-Mix, Low-Volume CNC Production

A shift is occurring in CNC manufacturing processes. Versatile high-mix, low-volume (HMLV) production is moving to replace some of the large-scale repetitive product processes. Flexibility is essential because of the diversity of parts, smaller batch sizes, and frequent changeovers with HMLV. The good news? Modern automation solutions are built with these complexities in mind. They […]

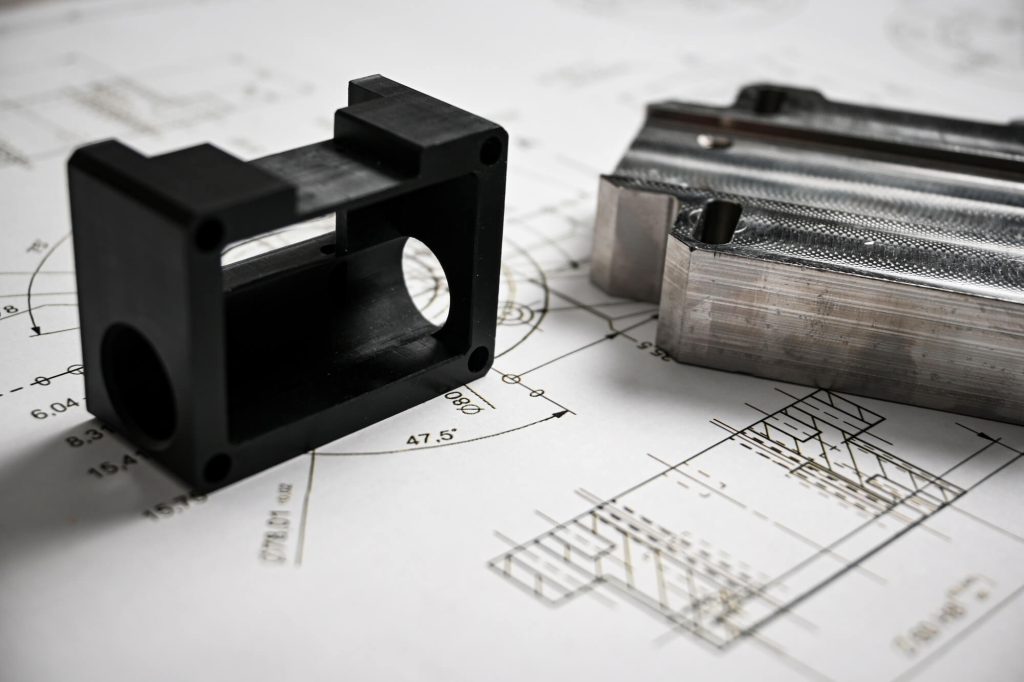

Optimizing CNC Machining through Proactive Design for Manufacturability

At Ben Machine, we prioritize design for manufacturability (DFM) to optimize product design, making machining easier, more efficient, and more cost-effective, while maintaining functionality and quality. But what is DFM? DFM is aligning engineering and production, especially during the design phase, to optimize every manufacturing aspect from start to finish and reduce effort and costs […]

Managing Efficient CNC Operations in Economically Uncertain Times

Navigating the CNC industry during economic uncertainty demands precision beyond machining operations. Efficient practices–from streamlining workflows to optimizing costs and resources–help safeguard profitability and resilience while ensuring reliability and meeting customer needs by managing lead times. Ben Machine is committed to actionable strategies that help maintain performance, adapt to changing markets, and thrive despite challenging […]

2025 Trends in CNC Machining: Prioritizing High-Mix, Low-Volume Production Excellence

Many CNC machine shops focus on the high-volume production market. They search for orders yielding 10,000 parts per year or more. However, Ben Machine is differentiated from them as we focus on high mix, low volume work that emphasizes the front work of setup and programming. In this article, we focus on the trends in […]

Navigating the Stratosphere: Meeting the Stringent Standards of Aerospace Cleanrooms

In industries like aerospace, cleanrooms are crucial for manufacturing, providing a controlled environment with ultra-low airborne particle levels. Since even the smallest contaminants can lead to catastrophic failures, cleanrooms help ensure that manufactured parts meet the industry’s high standards. The Role of Cleanrooms in Aerospace Engineering The aerospace industry relies on cleanroom environments for producing […]

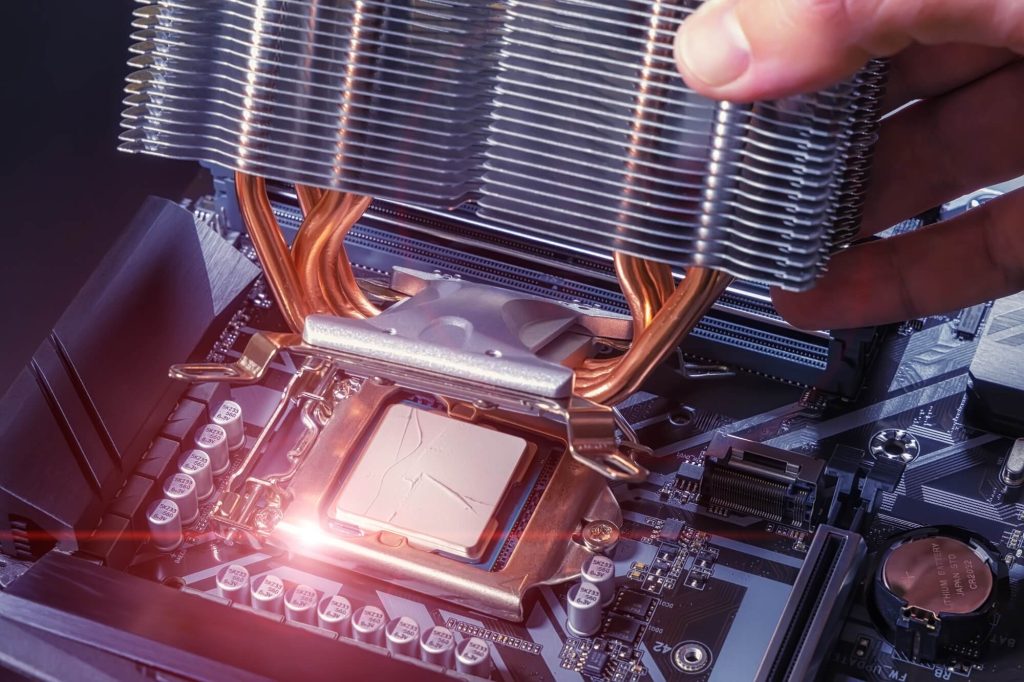

From Smartphones to Satellites: Aluminum’s Role in CNC Machined Electronics

It’s nearly impossible to overstate aluminum’s role in CNC machined electronics. After all, CNC machining helps to manufacture components for a wide range of everyday gadgets, from smartphones to satellites, and many of the components in these products are made from aluminum. Aluminum’s versatility and machinability are only two reasons that make it a preferred […]

The Heat is On: Managing Thermal Properties with Aluminum in Electronic Manufacturing

Heat management in electronic devices is challenging due to their increasing power density and miniaturization. As electronic components become more compact and powerful, they generate significant amounts of heat in a smaller space, leading to issues if not properly managed. Combining CNC machining and aluminum’s unique properties offers significant thermal management solutions for these electronic […]