Ethical Sourcing in CNC Machining: Building a Responsible, Traceable, and Sustainable Metal Supply Chain

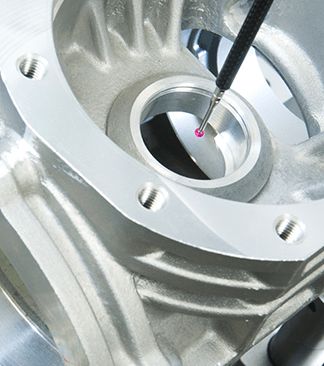

CNC machining is an automated manufacturing process that improves a part’s precision, efficiency, and repeatability. It’s vital in modern manufacturing because it can